This module is used to maintain finished goods and raw materials in bill of material, perform item assembly, provide reports on transaction and stock balance.

Go to Tools > Program Control > Module Setting

Check the checkbox of Bill of Material to enable it.

Stock Item Maintenance

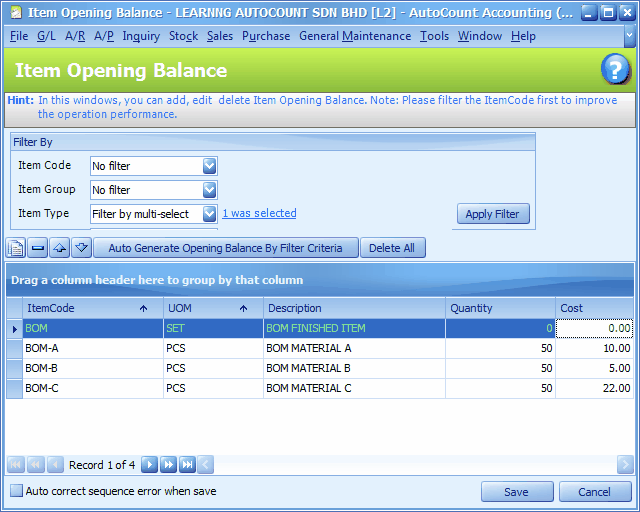

First of all, maintain stock items for BOM finished goods and materials, then key in their opening balances OR create purchase documents (if any).

In the following example, 'BOM FINISHED ITEM' is a finished goods, and its materials are: BOM-A, BOM-B, and BOM-C.

Item BOM Maintenance

We need to maintain Bill Of Material for such finished goods and its material items.

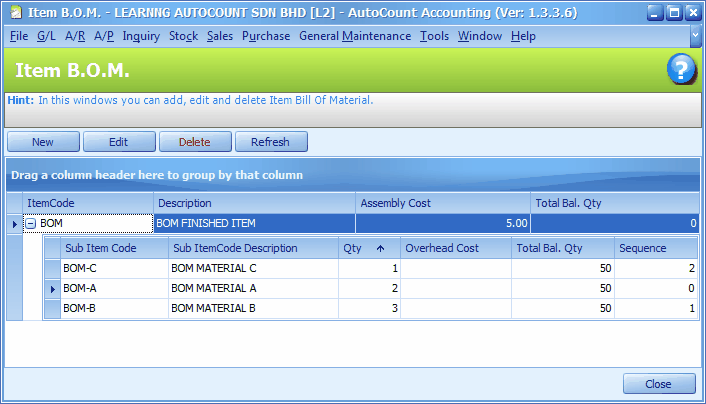

Go to Stock > More Stock Maintenance > Item BOM Maintenance

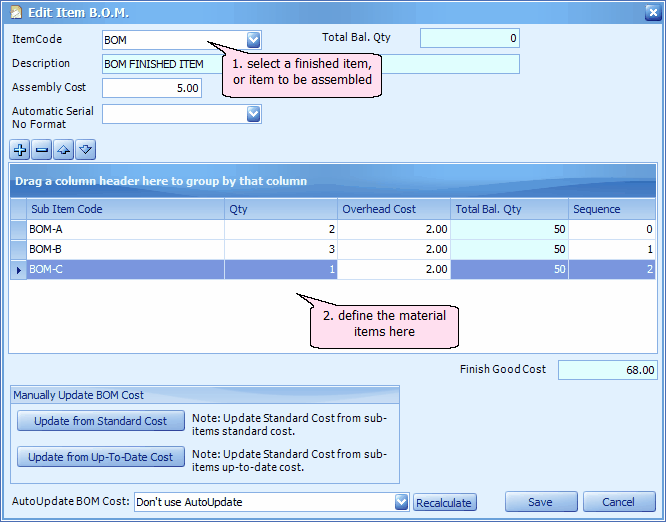

Click on New,

Item Code: assign finished goods' item code.

Total Bal. Qty.: balance quantity of this finished goods (auto displayed)

Description: description of this finished goods (auto displayed upon selection of Item Code)

Assembly Cost: key in (if any) amount of cost involved in assembling one unit of this finished goods, which will be included in Finish Goods Cost.

Automatic Serial No. Format: (if this is an item with serial number) select a serial numbering format so that the system will auto generate serial number upon creation of finished goods. To maintain the serial number format, go to General Maintenance > Document Numbering Format Maintenance, click on New, select Document Type: S#. After saved, it will appear under Category: Others.

Sub Item Code: click on '+' sign to add B.O.M. material items one by one.

Qty: the quantity of this material needed to assemble one unit of finished goods

Overhead Cost: overhead cost that will occur when using this material item to assemble finished goods (regardless of quantity)

Total Bal.Qty: current balance quantity of this material item (auto displayed)

Sequence: indicating the sequence order of material items.

Finish Good Cost: total assembly cost of one unit of B.O.M. finished goods.

Manually Update BOM Cost: to manually update (when needed) the Standard Cost of this finished goods either from sub-items Standard Cost or Up-To-Date Cost.

Auto Update BOM Cost: to automatically update the Standard Cost of this finished goods either from sub-items Standard Cost or Up-To-Date Cost whenever there is a change in that cost.

Recalculate: to recalculate the cost of this BOM finished goods based on latest updates.

Click on Save.

Click on '+' sign before Item Code to list the Sub-Items and details.

Related topics: 15035 BOM Finished Goods Cost column

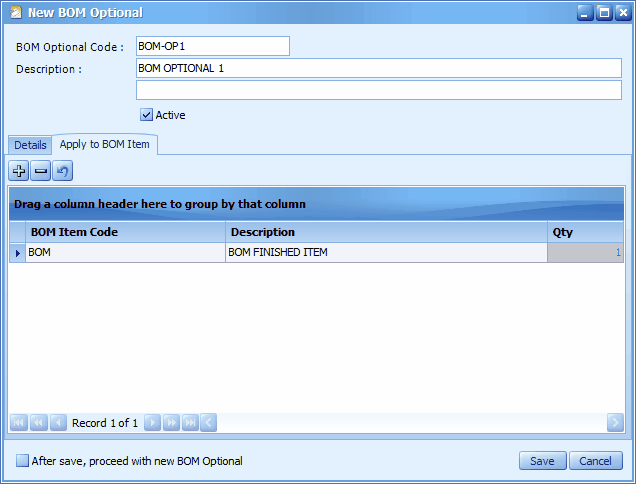

BOM Optional

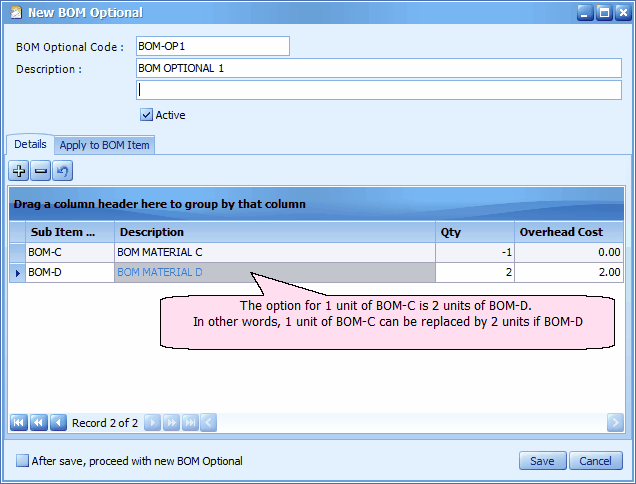

This is to maintain optional/alternative material items for BOM finished goods. It will be used in Stock Assembly and Stock Assembly Order.

Go to Stock > BOM Optional

Click on New,

BOM Optional Code: key in an optional code

Description: key in description of this BOM optional

Details tab: click on '+' button to assign sub-items... For example: to replace one unit of BOM-C (key in negative quantity value -1) with 2 units of BOM-D (key in positive quantity value 2).

Apply to BOM Item tab: click on '+' sign to assign which is (are) the BOM finishes goods that this BOM Optional can apply to.

Click on Apply to BOM Item...

Click on '+' sign to assign BOM finishes goods that this BOM Optional can apply to.

Click on Save..

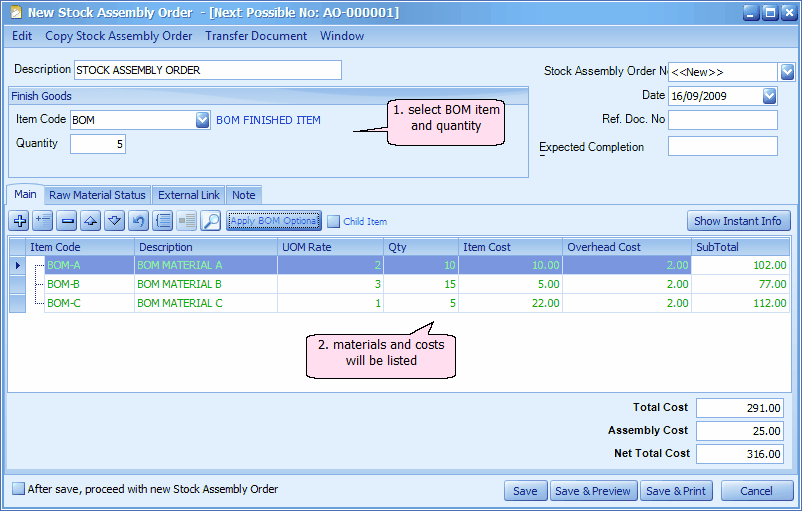

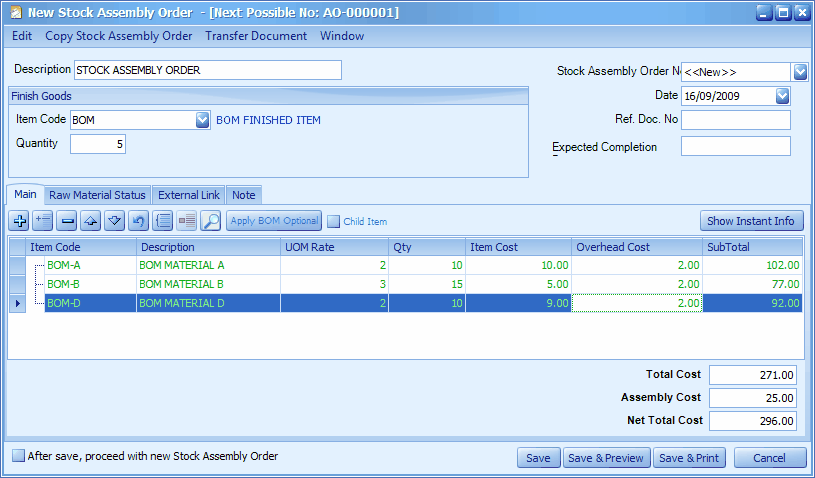

Stock Assembly Order

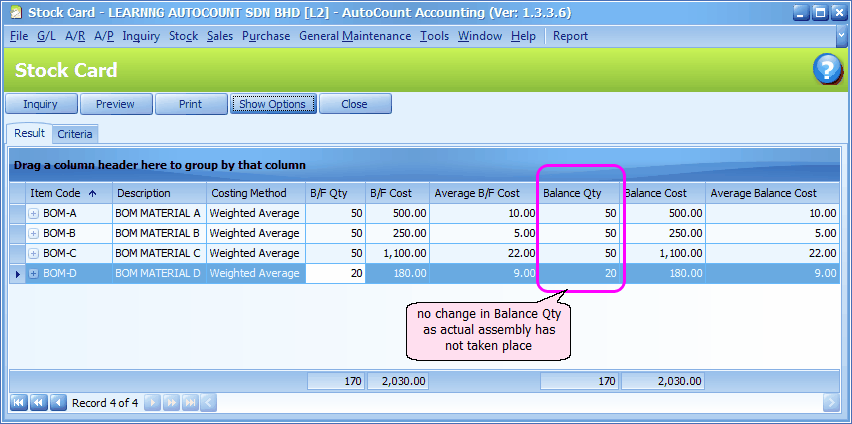

Just like the function of Sales Order or Purchase Order, Stock Assembly Order will not affect stock movement, it can be transferred to Stock Assembly and there will be an outstanding report on Stock Assembly Orders that have not been transferred.

Go to Stock > Stock Assembly Order

Click on Create a New Stock Assembly Order,

Transfer Document: you may transfer from Sales Order.

Description: description of this document

Stock Assembly Order No: auto running document number, next possible number is shown on the top of window. You may click on <<New>> to key in any document number.

Date: document date

Ref. Doc. No: key in reference document number (if any)

Expected Completion: key in expected date (or days) of completion. (For reference only)

Main tab: the related materials will be listed with the rate (the quantity of material item needed for one unit of finished goods), material item unit cost, overhead cost (lump sum) and sub total.

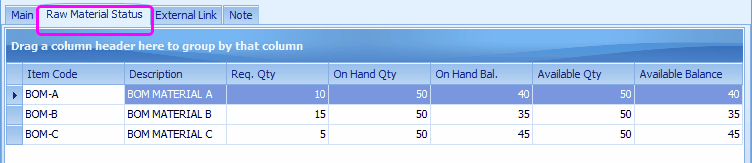

Raw Material Status tab: to show the total quantity of raw materials needed and stock availability.

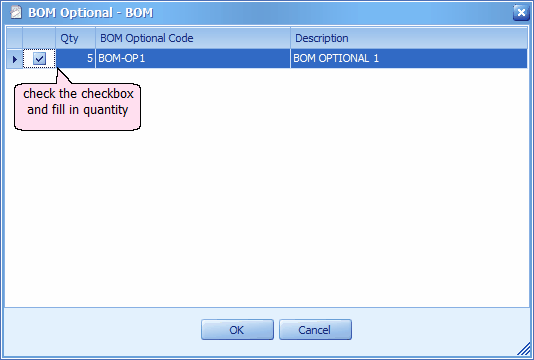

Apply BOM Optional: to apply BOM Optional that was maintained earlier, e.g. to substitute one or more of the material items.

Check the checkbox to select, fill in quantity, and click on OK...

Alternatively you may click on '-' and/or '+' signs to remove/add a material item or just edit item code, Qty, item cost, overhead cost and/or assembly cost.

View Stock Card Report...

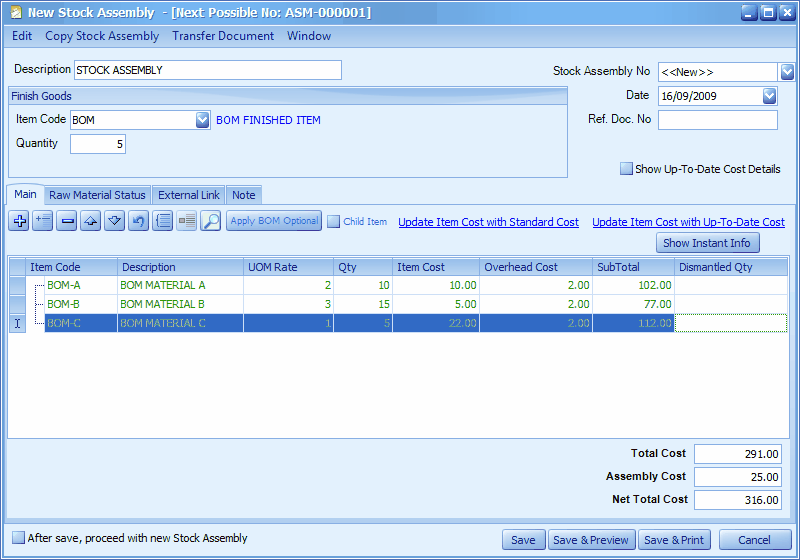

Stock Assembly

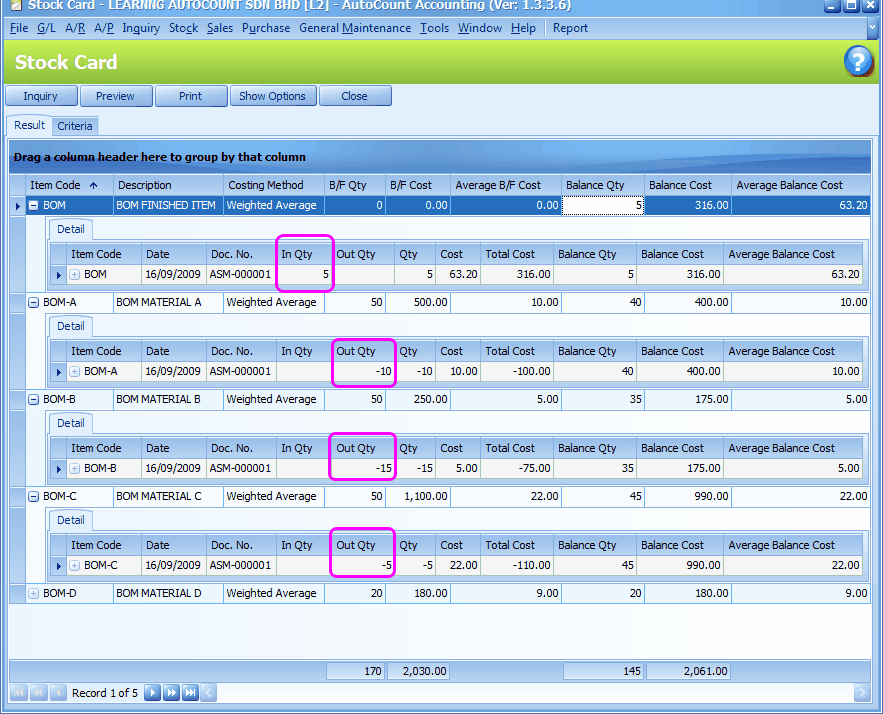

Stock Assembly is to assemble finished goods according to BOM setting. This transaction will increase stock quantity of finished goods and at the same time decrease stock quantity of material items.

Go to Stock > Stock Assembly

Click on Create a New Stock Assembly,

Select Item Code (finished goods to be assembled),

Key in quantity to be assembled,

Transfer Document: you may transfer from Stock Assembly Order.

Description: description of this document

Stock Assembly No: auto running document number, next possible number is shown on the top of window. You may click on <<New>> to key in any document number.

Date: document date

Ref. Doc. No: key in reference document number (if any)

Show Up-To-Date Cost Details: to display (at footer area) the up-to-date cost for the highlighted item.

Main tab: the related materials will be listed with UOM Rate (quantity of material item needed for one unit of finished goods), Qty (total quantity of material item needed for this transaction), material item unit cost, overhead cost (lump sum) and sub total.

Raw Material Status tab: to show total quantity of raw materials needed and stock availability.

Apply BOM Optional: to apply BOM Optional earlier maintained, e.g. to substitute one or more of the material items.

Child Item: this is to be used together with BOM Optional when Multi Level Assembly module is enabled.

Update Item Cost With Standard/Up-To-Date Cost: to update item cost with Standard Cost or Up-To-Date Cost.

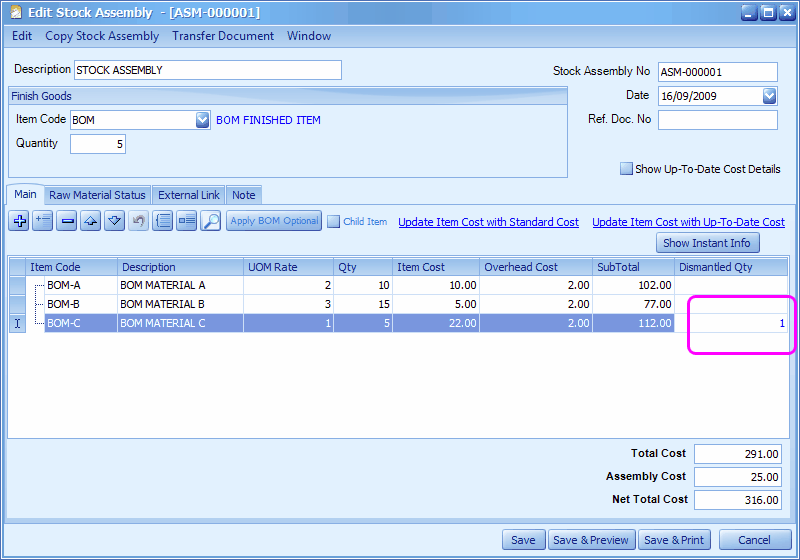

Dismantled Qty: quantity of this item that has been dismantled or taken out from this assembly.

Total Cost: total cost of material items including overhead cost.

Assembly Cost: total assembly cost, derived from: Assembly Cost per set X assembly quantity

Net Total Cost: will be used to calculate unit cost of this finished goods.

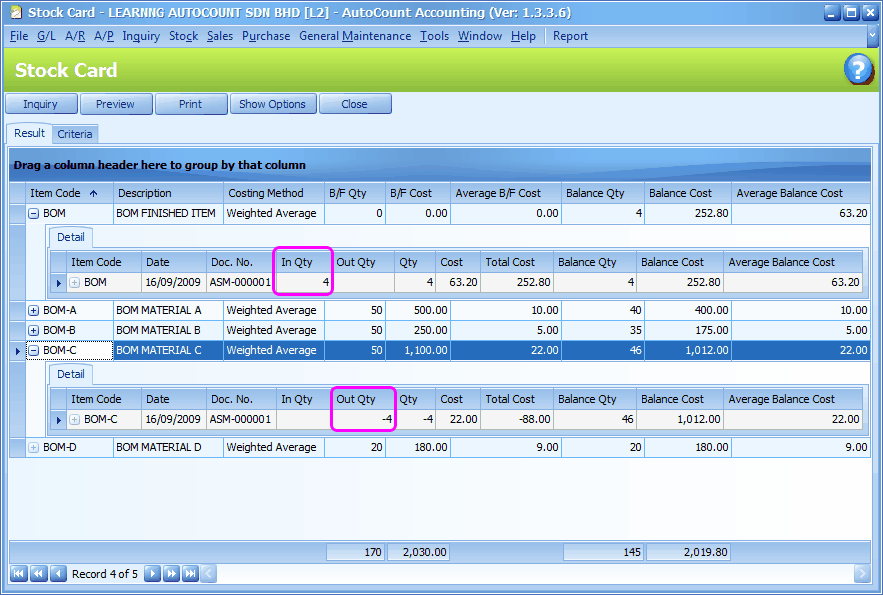

View the Stock Card Report again...

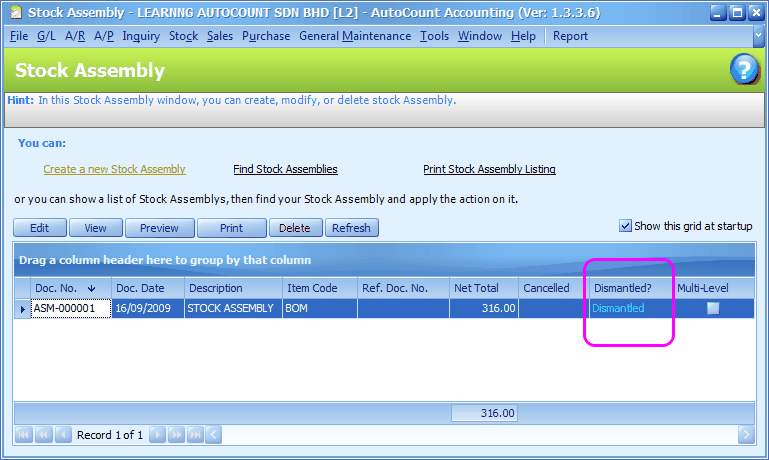

Dismantled Quantity

Dismantled quantity must be recorded when one or more material items were taken out from assembled item. The dismantled items will be returned back to store room (stock increase) and the quantity of assembled finished goods will be reduced accordingly.

Go to Stock > Stock Assembly

Highlight the item assembly that involved dismantled quantity, click on Edit,

Key in quantity value into the column of Dismantled Qty.

Click on Save..

View the Stock Card Report again...

Note: you may see that the balance quantity of material (BOM-C) and finished goods (BOM) were affected accordingly.

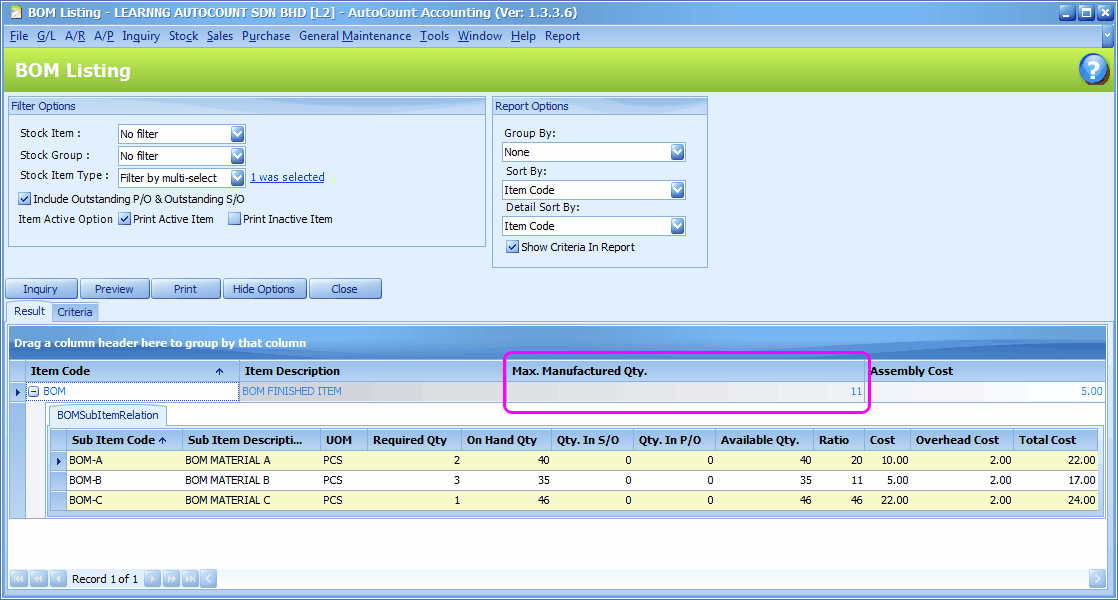

BOM Listing Report

To list all BOM items and show the maximum quantity (finished goods) that could be assembled based on currently available material items stock level.

Go to Stock > BOM Listing Report

Define filter options,

Click on Inquiry,

Click on '+' sign before Item Code to expand the details of sub-items. (or right click on column header and click on Expand All)

Max. Manufactured Qty.: the maximum quantity (finished goods) that can be assembled based on current level of stock (material items).

Ratio: the maximum rounded quantity that can be assembled based on this material item stock level. (take Available Qty and divide by Required Qty)

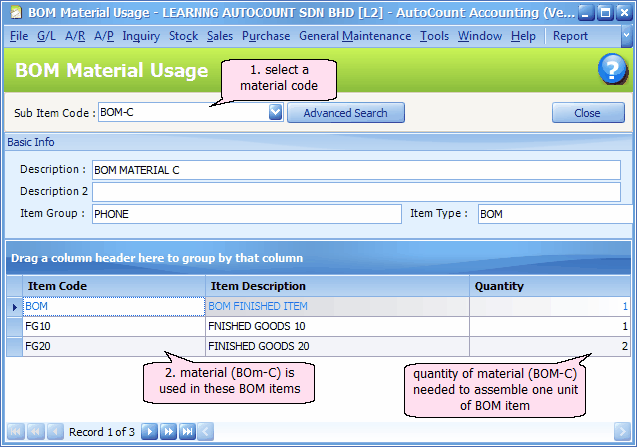

BOM Material Usage Inquiry

To check the usage of a material item, such as in which finished item and the quantity needed to produce one unit of that finished item.

Go to Inquiry > BOM Material Usage Inquiry

Select a material item code (Sub Item Code),

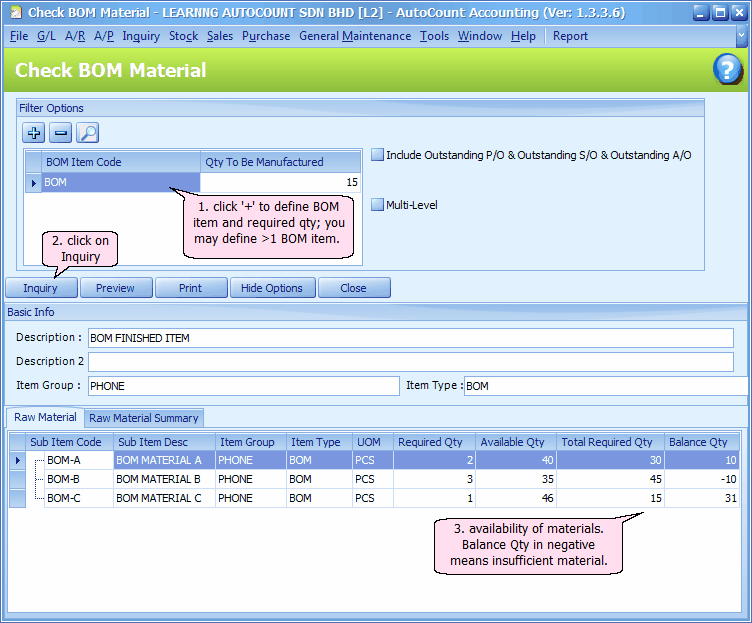

Check BOM Material Inquiry

To check the availability of material items if a certain quantity of finished goods is to be assembled.

Go to Inquiry> Check BOM Material Inquiry

Click '+' to assign a BOM Item Code (finished goods item code) and key in Qty To Be Manufactured, (you may add more than one BOM items)

Click on Inquiry,

Note: the negative value in Balance Qty means insufficient quantity of that material item.

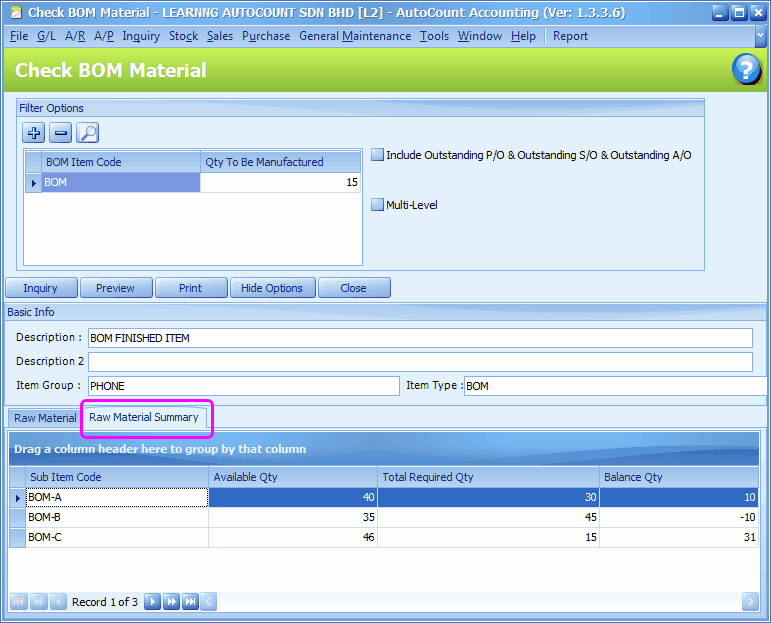

Click on Raw Material Summary tab,

_____________________________________________________________

Send feedback about this topic to AutoCount. peter@autocountSoft.com

© 2013 Auto Count Sdn Bhd - Peter Tan. All rights reserved.